Knowing Yourself & Supplier Selection Analysis for Tesla’s Battery Supply Chain

Explore and Select Suppliers Globally

Jose Vasquez

Supply Chain Analytics Essential

Prof. Yao Zhao

Spring 2025

Tesla Car's Evolution

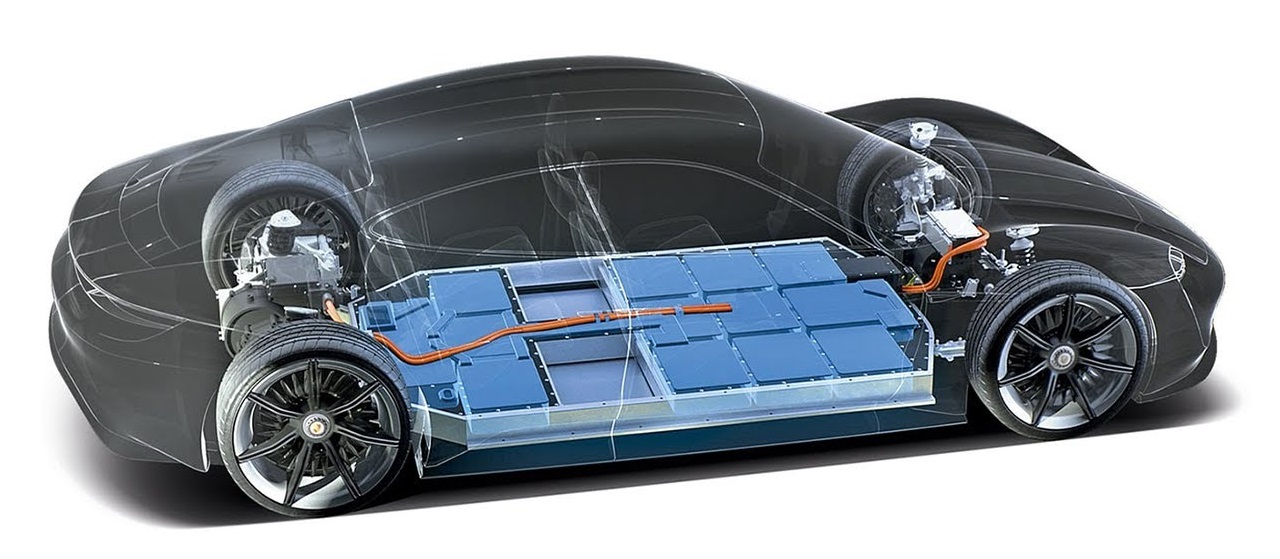

Tesla Car: Electric Vehicle

Tesla's market cap overtakes Ford's in 2017

It's Common for One Company to Invent Technologies but Suppliers to Take Over by Cost Advantage …

How to source globally to maximize benefits and minimize risks?

Benefits of Global Sourcing

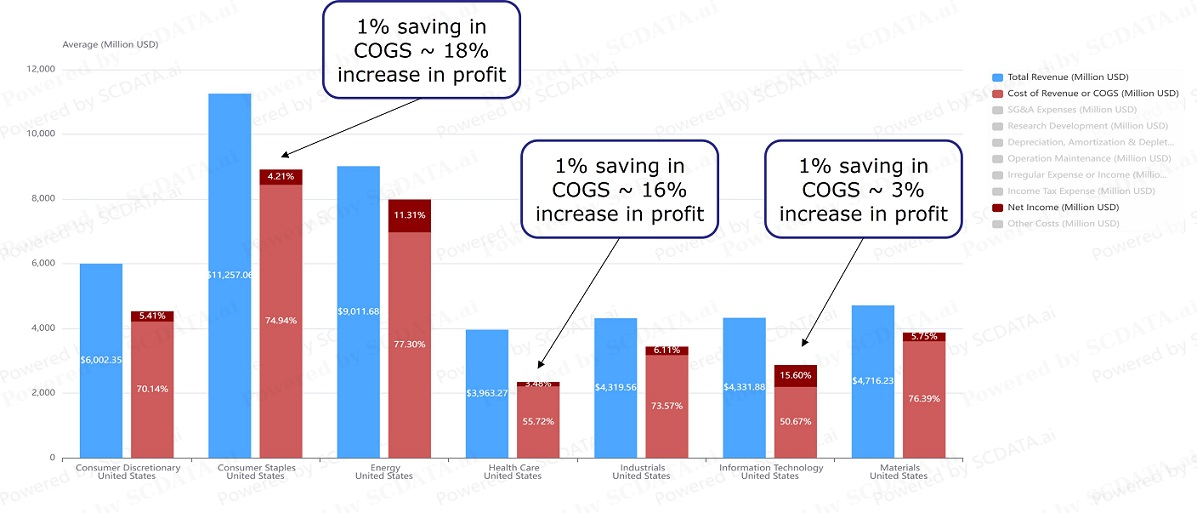

Sourcing can significantly improve net income and thus stock market performance!

Source: https://www.scdata.ai/project/19934

Sourcing Analytics

Evaluating Requirements and Supplier Selection Standards

Aligning supplier selection criteria with the company’s strategic objectives

Needs & Supplier Analytics

Knowing Yourself

EV Battery Supplier Selection Criteria

Supplier Selection Criteria

Based on Intel’s supplier intake framework6 and Boeing’s evaluation methodology3, Tesla’s criteria should prioritize:

Technical capability: Ability to innovate (e.g., solid-state battery technology).

Quality compliance: Adherence to ISO 9001 and Tesla’s proprietary standards.

Cost competitiveness: Willingness to participate in Tesla’s cost-reduction initiatives.

Supply chain resilience: Geographic diversification to mitigate risks (e.g., avoiding over-reliance on Chinese suppliers).

ESG alignment: Commitment to reducing carbon emissions and ethical labor practices.

Supplier Intelligence

Exploring & identifying potential suppliers globally

Market Intelligence and Suppliers

Potential Suppliers (EV Battaries)

|

Company |

Founded |

Location |

|

Contemporary Amperex Technology Co., Ltd. (CATL) |

2011 |

Ningde, Fujian, China |

|

BYD Co., Ltd. |

1995 |

Shenzhen, Guangdong, China |

|

LG Energy Solution Ltd. |

2020 |

Seoul, South Korea |

|

China Aviation Lithium Battery Co., Ltd. (CALB) |

2009 |

Luoyang, Henan, China |

|

Panasonic Energy of North America |

1918 |

Sparks, Nevada, Unites States |

|

Guoxuan High-tech Power Energy Co., Ltd. |

2006 |

Hefei, Anhui, China |

|

Samsung SDI Co., Ltd. |

1970 |

Yongin-si, South Korea |

|

SK Innovation Co., Ltd. |

1962 |

Seoul, South Korea |

|

Sunwoda Electronic Co., Ltd. |

1997 |

Shenzhen, Guangdong, China |

|

Farasis Energy |

2002 |

Hayward, California, United States |

Bargaining Power Analysis

What is my leverage? Who has the bargaining power?

Power of Bargaining

Summary Table: Tesla’s Bargaining Power Over EV Battery Suppliers

| Supplier | Battery Type | Tesla Bargaining Power | Notes |

|---|---|---|---|

| Panasonic | Cylindrical (18650, 2170) | High | Long-time partner, joint Gigafactory |

| CATL | LFP | Medium to Low | Leading supplier, dominant in China |

| LG Energy | NCM, NCMA | Medium | Competitive but less dependent |

| BYD | LFP Blade | Low | Also a rival EV maker |

| Tesla (in-house) | 4680 | Very High | Vertical integration in progress |

Supplier Benchmarking

Compare suppliers’ pricing, profitability, health and supplying capability

Supplier Benchmarking of EV Battaries

Here are the key benchmark variables for EV battery suppliers:

Price per kWh

Profitability

Production Capacity

Technology Type (e.g., LFP, NCA, 4680)

Supply Chain Integration

Raw Material Access

Geographic Location

Delivery Lead Time

Quality & Performance Metrics

R&D Investment

Client Dependency

Contract Duration

ESG Compliance

Government Subsidies/Incentives

Innovation Rate

Scalability

Financial Stability

Automation Level

Vertical Integration

Flexibility in Customization

Profitability Analysis

Suggested Suppliers for Tesla EV Batteries